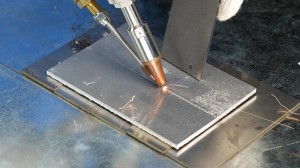

A cikin masana'antar zamani, aikace-aikace naSifen 2000w Laserying Welding injunanDon walda aluminium m ƙarfe na ƙasa yana ƙara yawan yaduwa. Koyaya, don tabbatar da walwala da aminci, mahimman al'amura masu zuwa suna buƙatar tunawa.

1. Jiyya na gaba kafin waldi

Filin dodel a farfajiya na ƙarfe na ƙarfe na iya shafar ingancin waldi. Active jiyya na jiki dole ne ya za'ayi don cire fim ɗin oxide, stain mai da sauran impurities. A lokacin da wani kayan aikin jirgin sama da aka kunna a cikin Aluminum firam, saboda jiyya na jiyya, babban adadin pores da fasa da fasa sun bayyana a Weld, da kuma adadin matakan cancanta. Bayan inganta tsarin magani, ƙimar cancanta ya tashi sama da 95%.

2. Zabi na sigogin da suka dace

Selding sigogi kamar su ikon laser, saurin saurin da kuma matsayin mayar da hankali suna da matukar muhimmanci. Don faranti na aluminium tare da kauri na 2 - 3mm, ikon 1500 - 1800w ya fi dacewa; Ga waɗanda suke da kauri daga 3 - 5mm, 1800 - 2000w ya dace. Saurin walding ya dace da iko. Misali, lokacin da wutar ta ce 1800w, saurin 5 - 7mm / s yana da kyau. Matsayin mayar da hankali kuma yana shafar tasirin waldi. Mayar da hankali ga faranti na bakin ciki yana kan farfajiya, yayin da lokacin farin ciki, yana buƙatar zurfafa ciki.

3. Gudanar da shigar da zafi

Karfe na aluminum yana da babban abin da ake nufi kuma yana daɗaɗen asarar zafi, wanda ke shafar kunnawa da ƙarfi. Ana buƙatar ainihin ikon shigar da zafin rana. Misali, lokacin da aka samar da sassan kayan aiki na Aerospace aluminum, rashin iko na shigarwar zafi wanda ya haifar da fonma da Weld. An warware matsalar bayan inganta tsarin.

4. Aikace-aikacen Gas

GAS GASKIYA GASKIYA na iya hana waye shaye shaka da mamaki. Argon, Helium ko gaurayawar su ana amfani da su, kuma ragin kwararar da kuma busa ja-gora ya kamata a daidaita shi da kyau. Bincike ya nuna cewa yawan adadin Argon na 15 - 20 l / min da kuma hanyar hurawa da ta dace na iya rage rawar jiki.

A nan gaba, ana tsammanin cewa kayan aiki mai hankali da kuma kayan kwalliyar laser da mafi hikima zasu fito, da kuma sabbin matakan walda da kayan za su inganta aikace-aikacen sa. A ƙarshe, ta hanyar bin waɗannan matakan, kawai ta bin ƙwarewa da kuma inganta ƙwarewa da inganta tsari zai iya yin amfanin welding na laser don haɓaka masana'antar masana'antu.

Lokaci: Jul-12-2024