Kungiyar Binciken Zang Liang ta Binciken kungiyar ta Suzhou don binciken Kimiyya da Fasaha na Laser Micro-nanano, kuma a hade da shi da bugun jini kai tsaye, a karo na farko ta tabbatar da rubuta kayan aikin microcronins da Circhients irin su auties, Transctions da kewaye da kebulewa, saboda haka tsawaita yanayin aikace-aikacen laser, a wasu filayen suna da mahimman tsammanin aikace-aikace. Kwanan nan an buga sakamakon binciken a cikin "Sadarwa ta Yanayi" a karkashin taken "Laser Buga Microecronics".

Buɗe kayan lantarki shine fasahar da ke fitowa wacce ke amfani da hanyoyin bugu don samar da samfuran lantarki. Ya hadu da halayen sassauci da keɓancewa da sabon ƙarni na samfuran lantarki, kuma zai kawo sabon juyin juya halin fasaha zuwa masana'antar ƙwayoyin ƙwayoyin cuta. A cikin shekaru 20 da suka gabata, Inkjet da suka gabata, Inkjet Buga, Canja wurin Laser-jawo), ko wasu dabarun buɗewa ba tare da bukatar buƙatar babban yanayin tsabtatawa ba. Koyaya, girman fasalin fasalin na hanyoyin buga littattafai galibi suna kan tsari na dubun kan Microns, kuma galibi yana buƙatar haɓaka aikin aiki mai yawa don cimma aikin na'urori masu yawa don cimma aikin na'urori masu aiki. Fasaha Laser micro-nano yana amfani da ma'amala marasa daidaituwa tsakanin hanyoyin da ke tattare da kayan aikin da ke da wahalar cimmawa ta hanyar gargajiya da ke da shi. Koyaya, yawancin tsarin laser na yanzu suna da ƙiroti na Nano-Nano-Nano-Nano-Nano-Nano sun ƙirar kayan polymer guda ɗaya ko kayan ƙarfe. Rashin wadatar Laser kai tsaye hanyoyin don kayan aikin semiconductor su kuma yana da wahalar fadada aikace-aikacen fasaha na laser micro-Nano zuwa filin na'urorin microcronic na'urorin.

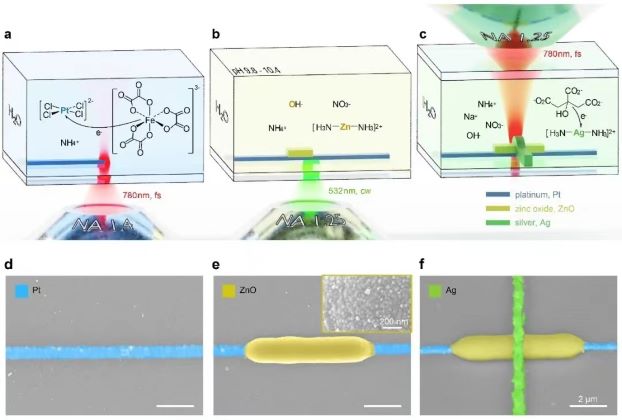

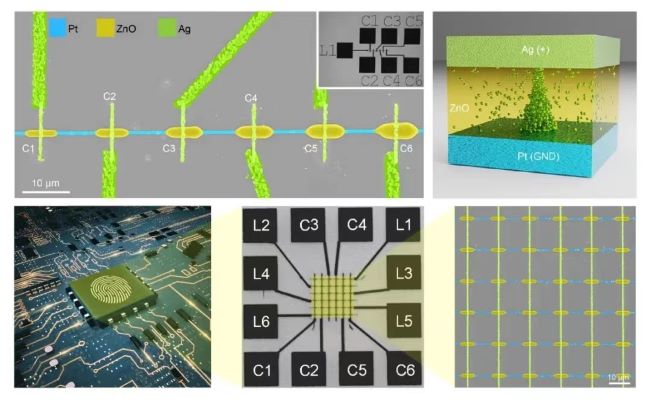

A cikin wannan rubutun, mai bincike yang Liang, tare da hadin gwiwa tare da masu bincike a Jamus da AG) na kayan aiki na PT da kuma karamar girman fasalin Pt da kuma karamar girman fasalin. Wannan nasarar yana sa zai yuwu a tsara ƙirar da buga masu kasuwanci, semiconducontorors, wanda ke inganta daidaito, sassauci sosai, da kuma ikon bugun na'urorin micrelecronic. A kan wannan, ƙungiyar bincike ta samu nasarar gano yadda aka haɗa yankin Laser kai tsaye, membaimasashe da da'irar ɓoyewar jiki waɗanda ba su da tushe (Hoto na 2). Wannan fasaha tana da jituwa tare da buga rubutun Inkjet da sauran fasahar, kuma ana sa ran za a iya fadada su ga kayan aikin p-daban-daban da n-nau'in kayan aikin microcronic guda uku.

Taƙaitaccen labari: HTTPS: //www.nathe.com/articles/S41467-023-7

Lokaci: Mar-09-2023