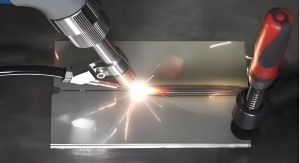

A cikin filin masana'antar yau, daAir-coored hannun Laser Welding InjinYa zama sanannen zaɓi don walding masana'antu tare da kyakkyawan aikinsa da fa'idodi masu mahimmanci. Don haka, menene fa'idodinsa na musamman? Bari mu bincika.

I. SIFFOFIN MULKI NA BIYU NUNA CIKIN SAUKI

- Haɗin Laser: Rahotsi na Laser na gama-gari shine tsakanin 800w - 2000W, wanda zai iya biyan bukatun waldi na daban-daban na gaske.

- Welding Speed: Saurin walding na iya kai 5m / min - 10m / min, wanda ya inganta haɓakar samarwa da takaita hanyar samarwa.

- A tabo diamita: Matsayin diamita yana tsakanin 0.2mm - 2mm. Amintaccen tsari na iya samun maki mai kyau da kuma tabbataccen waldi.

- Mitar aiki: Mitar aiki shine 20khz - 50KHz. Hanya mai girma tana tabbatar da ci gaba da kwanciyar hankali na walda.

- Kayan aiki: nauyin kusan 20kg - 60kg yana ba da damar mai aiki don riƙe kuma yana sarrafa shi sauƙi da sassauci yanayin waldios.

- Bayani girman: karamin ƙira tare da tsawon 50cm - 500cm, shekara ce ta kashi 40cm - 50cm, da tsawo na 40cm - 60cm ba ya mamaye sararin samaniya da yawa kuma yana dauwari a cikin yanayin aiki daban-daban.

- Abubuwan da ake buƙata na wutar lantarki: yawanci, yana goyan bayan shigar da wutar lantarki na 220v ko 380v, daidaita da mahimman yanayin samar da masana'antu da yawa.

- Matsakaicin kayan walda da aka zartar: ya dace da kayan ƙarfe daban-daban kamar bakin karfe, carbon karfe, aluminum reden, da jan ƙarfe, aluminum reshe na masana'antu daban-daban.

- Bayanai mai amfani da kayan aiki: Idan aka kwatanta da kayan aikin walding na gargajiya, ana iya samun kuɗin ku da yawa don kamfanonin da aka yiwa kamfanonin lokacin aiki.

II. Kayan aiki mai ƙarfi don inganta ingancin aiki

DaAir-coored hannun Laser Welding Injinyana da ingancin aikin aiki tare da ingantaccen aikinsa. Misali, a cikin masana'antar samar da kayayyaki, yana ɗaukar sa'o'i da yawa don kammala walda na hanyoyin da ke tattare da hanyoyin mallaka. Koyaya, bayan da bin daddamar da Lakeld Lakeld Lakeld Lakelding na'urori Injin, Welding lokacin ba ta gajarta zuwa dubun mintuna. A saurin saurin sauri da ingancin walƙiyar sikelin ya kara yawan wucewar lokaci guda da rage lokacin da kuma albarkatun da aka ɓata saboda sake aiki.

III. Mummunar farashi mai mahimmanci

- N sharuɗɗan yawan amfani da makamashi, fasaha mai inganci da tsarin sarrafa iko yana sanya ƙananan kayan aikin Laser-sanyaya yayin aiki, da kuma amfani na dogon lokaci na iya ajiye kuɗin kashe kudi mai yawa.

- Dangane da farashin kayan aiki, sarrafawa mai walda yana rage asara ta zahiri yayin aiwatar da walding, kuma yana inganta farashin kayan albarkatun ƙasa.

- Hakanan ana rage farashin kulawa sosai. Tsarinsa na tsayayye da tsari mai sauƙi yana rage mita da farashin raguwar kayan aiki da kiyayewa.

IV. Haɗin da ba a haɗa shi ba a cikin aiki

- Tsarin bayyanar kayan aiki shine Ergonomic, da rike yana jin dadi, kuma ba abu mai sauƙi ba ne don samun fatigued a lokacin aiki na dogon lokaci.

- Injinan kwamfuta na comple-kwamfuta mai sauki ne kuma mai hankali, kuma aikin aikin ya bayyana kuma mai sauƙin fahimta, ba da izinin masu aiki da sauri.

- Tsarin tsari mai hankali mai hankali yana ba masu aiki don sauƙaƙe sigogi na waldi dangane da ayyuka daban-daban na walda.

A ƙarshe, daAir-coored hannun Laser Welding InjinYa nuna fa'idodi masu mahimmanci a fagen walding na masana'antu tare da ƙayyadaddun kayan aikinta mai ƙarfi, ingantaccen aiki, sahihiyar tanadi mai tsada da kuma hanyoyin biyan kuɗi. Ko dai ya inganta ingancin samarwa, rage farashin samarwa, ko bayar da masaniyar aiki mai dacewa, zaɓi ne mai dacewa. An yi imanin cewa a nan gaba, zai taka muhimmiyar rawa a cikin ƙarin filayen da inganta ci gaba da ci gaban masana'antar masana'antu.

Lokaci: Jul-09-2024